A well-maintained machine is a long-lasting asset, ensuring reliability and cost efficiency.

Enhancing Equipment Lifespan Through Strategic Maintenance Plans

- 3678

- 3

In industrial operations, equipment represents a significant investment. Ensuring that this investment delivers maximum value requires a strategic approach to maintenance. At Assinov, we specialize in designing tailored maintenance plans that not only enhance equipment lifespan but also improve efficiency and reduce long-term costs.

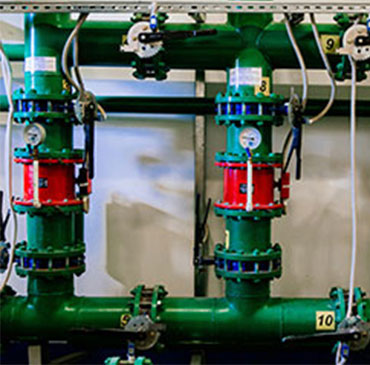

Routine maintenance is the backbone of any strategic plan. Regular servicing and inspections help identify potential issues before they escalate, minimizing wear and tear on equipment. At Assinov, we implement systematic maintenance schedules tailored to the specific requirements of each machine, ensuring optimal performance over time.

No two machines are the same, and their maintenance needs differ accordingly. Assinov designs strategic maintenance plans based on factors such as equipment type, usage patterns, and operating conditions. This personalized approach ensures that every asset is cared for in a way that maximizes its lifespan and efficiency.

Modern technology has transformed the way maintenance is performed. At Assinov, we integrate advanced tools like predictive analytics and IoT-enabled monitoring systems into our maintenance plans. These technologies allow us to anticipate potential issues and take preventive action, minimizing downtime and costly repairs.

Strategic maintenance is an investment, but one that delivers measurable returns. By extending equipment lifespan and preventing expensive breakdowns, businesses save significantly in the long run. Assinov’s maintenance plans strike the perfect balance between upfront costs and long-term benefits, ensuring value at every stage.

Enhancing equipment lifespan through strategic maintenance plans is more than just good practice—it’s a necessity in today’s competitive industrial environment. At Assinov, we combine expertise, technology, and a personalized approach to deliver maintenance solutions that protect your investments and keep your operations running smoothly. Invest in strategic maintenance today to secure a more reliable and cost-efficient future.

Sarah

This article makes a great case for strategic maintenance. Could you share an example of how Assinov has used predictive analytics to improve equipment performance?

Assinov Team

Thank you for your question, Sarah! In a recent project, we implemented IoT-enabled sensors on a client’s production line to monitor real-time performance data. By analyzing this data, we detected early signs of wear in critical components, allowing us to schedule maintenance before a breakdown occurred. This approach significantly improved the equipment's reliability and reduced downtime.